Today the doors of the distillery in Antigua Carretera de Barcelona (Puçol) open like the first day.

Uncle Pepe Plà didn’t imagine that his business survive wars, floods, famines and countless economic crises, but over a century later, his legacy is more alive than ever.

The company is now a replica of that originally launched in late SXIX. Nothing has changed, everything is the same. The office, the barrels, the still, the laboratory, the courtyard …, small facilities that keep centuries-old treasure still used daily. Here are few machines, the hand of man is the main engine of job. “Many people are surprised when we visit and see how we work. But I tell you that what we do is craft, “explains José Ripoll, great-grandson of the founder and current manager of the company.

If you want to visit the distillery, click here, book your day on the calendar, tell us how many people you are and just 6 € euros have private guided tour and a special end; a tasting lunch Pla product.

If against our calendar does not suit your requirements we invite you to see this virtual tour or carry out small tour of the most representative objects that have the Distillery to his credit.

Distillery facade

The facade dates from 1890 Distilleries Pla, the year of the founding of the company. The founder, Uncle Pepe Pla was projected onto the facade ceramística the Valencian tradition. On a pediment of classic facade is drawn in “taulell Valencia” (Valencian brick) the name of the company “Distilleries PLA, anisette factory, liqueurs and syrups”, and as an early product advertising is also written cognac bricks white and blue, as was the coñac (in Spain known as Brandy) most important product since the inception of the company.

The brick on the facade is drawn from 1890 is Valencia bill. It was manufactured by Fabresa, a ceramic company from Lucina Cid (Castellón) that still continues.

This uniqueness that has the facade of the factory has earned him special protection by the municipality of Puçol. Distillery border is protected by its cultural and tourist interest and can not be changed.

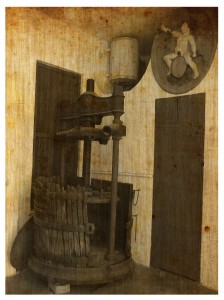

Cage presser. 1890.

In the beginning, the Pla Distilleries acquired most of muscat grape variety that is produced in the region of l’Horta.

The mechanism was simple; the basket of grapes are filled, a lid was put to pressure and pulled all the fruit and juice. From those first presses in our cellar we still have two barrels with which we make the Moscatel Superior.

Brandy barrels Vell. 1890.

Here’s great treasure lies Pla Distilleries. In the “mother barrel”, 12,000 liters of Brandy Vell, the great book that has made known throughout Spain Distilleries Pla saved. This type of oak barrels they are also called holandas, a name that extends low alcohol spirits. The nickname stems from the trade of Spanish wine producers filed with the Netherlands where surplus production sent as brandy after the Dutch became the spirits including brandy. Pla distilleries only sells 600 bottles a year of Brandy Vell to ensure the exclusivity of the product.

Still. 1890.

It is a tool whose operation has not changed since its invention. It was created by the Persian scholar Al-Razi in the S. X for creating perfumes, medicines and fruits from fermented alcohol. It is made of copper because it is a material that provides taste alcohol, resists acids and conducts heat well. Still commonly called pear for completion abombada.Un classic still like ours consists of a boiler, a capital, gooseneck and cooling assembly. Steps to distill:

1. Heat the mixture to be distilled in the boiler.

2. Evaporate the spirit we want to distill the mixture. You only need to increase the temperature a xxx degrees, since the evaporation temperature is less alcohol than water.

3. Increasing the temperature will separate the more volatile products forming the mixture. These products need them in liquid, that is why condensation process begins. The components begin to ascend, since the capital and then to gooseneck by the gas condenses by lowering of temperature, and will be collected in the final phase in liquid, helped by the cooling assembly.

These are only the most important elements of the distillery but much more to keep great stories and well worth knowing. So we invite you to visit us. Just click here and book the day you prefer.